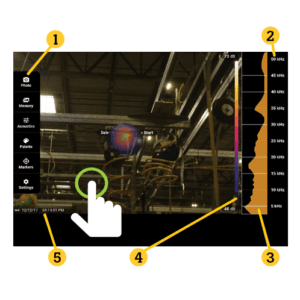

Product Overview

The first industrial acoustic camera turns sound waves into real-time image, to accurately pinpoint leaks at a glance.

Detect leaks based on ASTM

E1002-11 Standard.

Detect and locate compressed air, gas and vacuum leaks up to 70m.

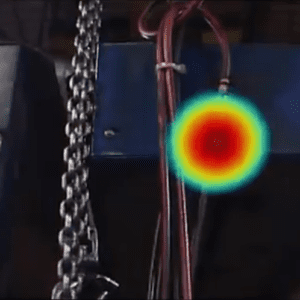

SoundMap™ technology allows visualisation of both acoustic and visual image.

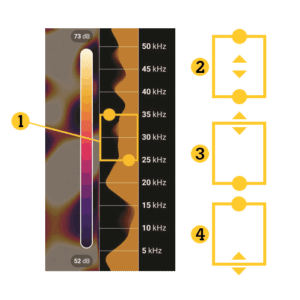

Ultrasonic detection up to 52kHz.

Leaks Visualisation

Inspections are done five to ten times faster by spotting leaks on the screen over live image

Ultrasonic Range

Detects leaks even under noisy conditions.

For Compressed Air, Vacuum, Gas or Steam

Detects leaks of any type of compressed gas, including vacuum leaks.

Intuitive Interface

Little to no training required. First time users can start finding leaks within minutes.

Based on Sound

Independent of ambient temperature or air/gas temperature, no matter indoors or outdoors.

Report Leaks by Pictures

Easy tagging and communication of the exact location of leaks to teams fixing them.

The first industrial acoustic camera featuring Fluke SoundSight™ Technology

Fine tune frequency range gradually until the leak is detected

View the source of the leak using combined SoundMap™ and visual image

Leak detection with Fluke ii900

Quickly pinpoint location of leaks at a glance

Take pictures to save leak locations

See multiple leaks on a single image

Easily record and share pictures and videos for reports

Never leave air leaks unattended again

Did you know that compressed air can account for 40% of wasted electricity?*

Locating leaks in compressed air, gas and vacuum systems has been time-consuming and tedious–until now.

With the Fluke ii900 Sonic Industrial Imager your maintenance team can quickly pinpoint the location of compressed air, gas and vacuum leaks in a matter of minutes.

With SoundSight™ Technology you can see the sound leaks produce, even from a distance, even in noisy industrial environments.