Simplify Connectivity for Smart Manufacturing

Enabling IIoT connectivity to perform remote monitoring and predictive maintenance, and transform your business

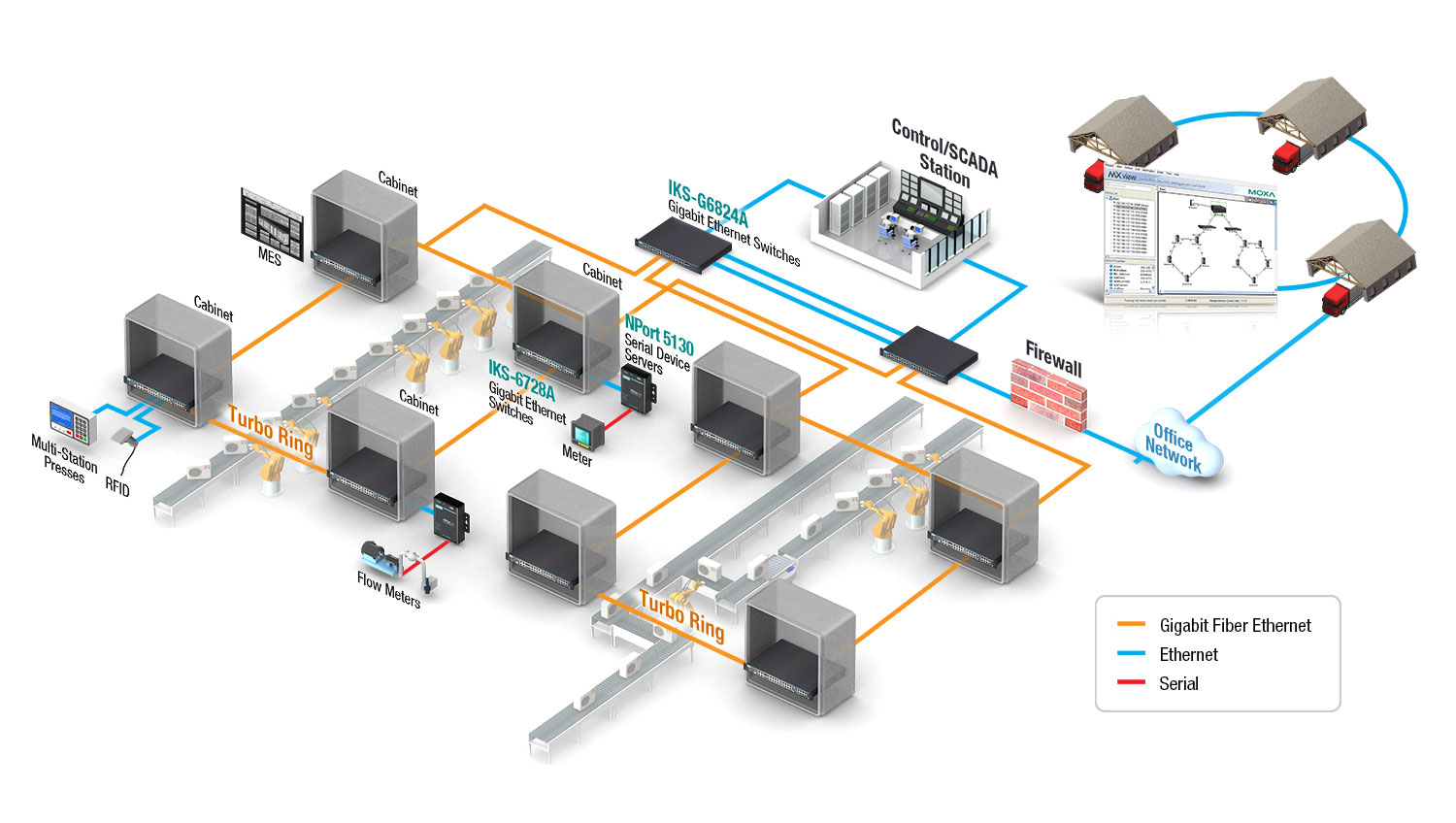

Connecting a large variety of subsystems and machines to perform remote monitoring

Real-time KPIs and dashboards, displaying accurate data of shop-floor operations, give managers valuable insights as to when and where they need to adjust their production planning. Therefore, a resilient and reliable network that connects a large number of existing data sources from various systems is critical. Find out how to address the challenges in connecting various systems and managing large networks to perform remote monitoring.

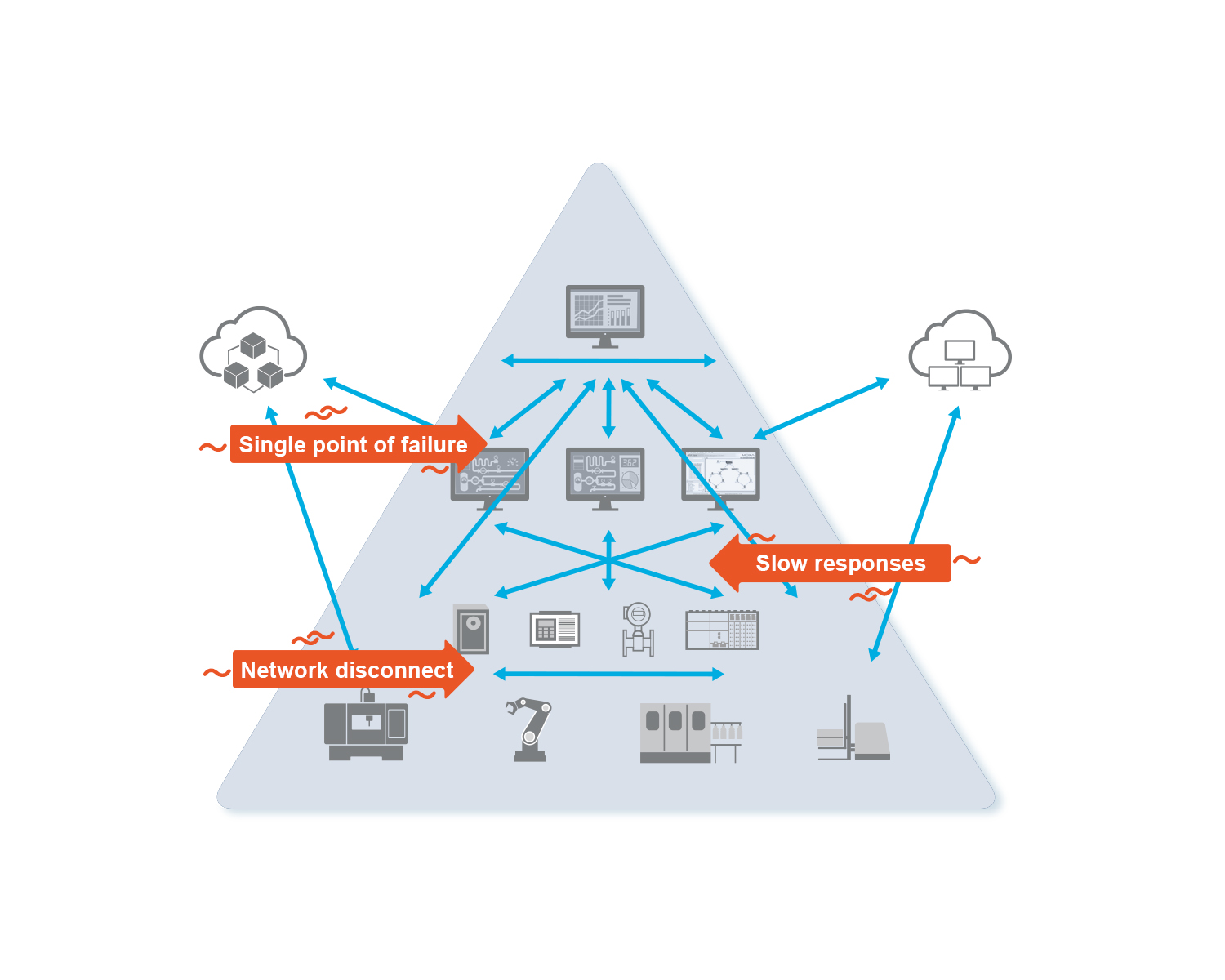

Connecting Various Systems Causes Network Outage

Connecting all the different OT subsystems makes the manufacturing processes transparent to managers. However, an interconnected network can become unstable or cause entire network outages—even though those systems have worked perfectly independently before. What if we can simplify network reliability to connect your various systems?

IIoT Connectivity:

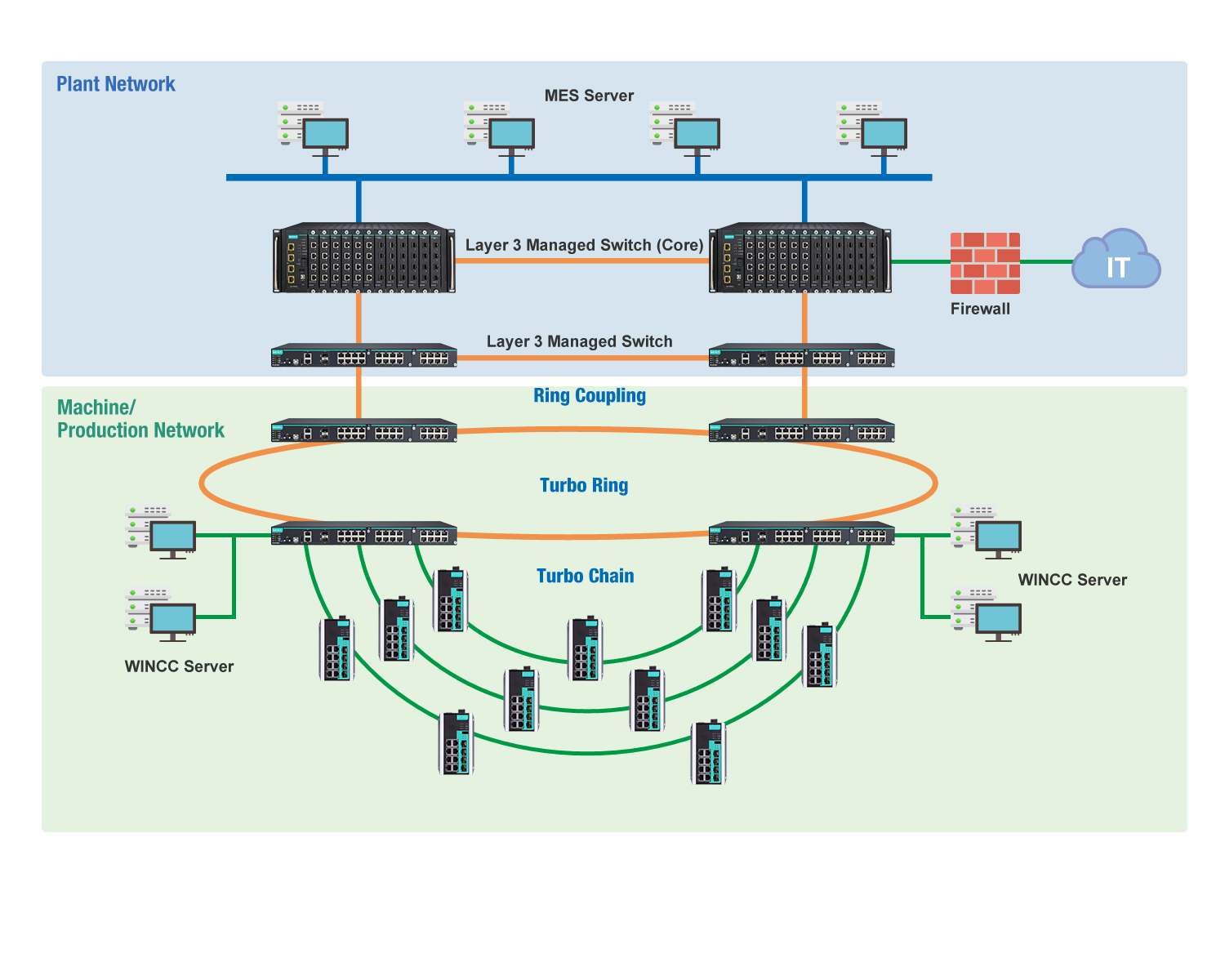

Connecting different subsystems that consist of commercial and industrial network devices

Problems:

- Commercial network devices cannot reliably perform 24-7 daily due to the many interferences, e.g., EMC and surge, in OT environments.

- Networks are not resilient enough

- Unmanageable interoperability

Simplified:

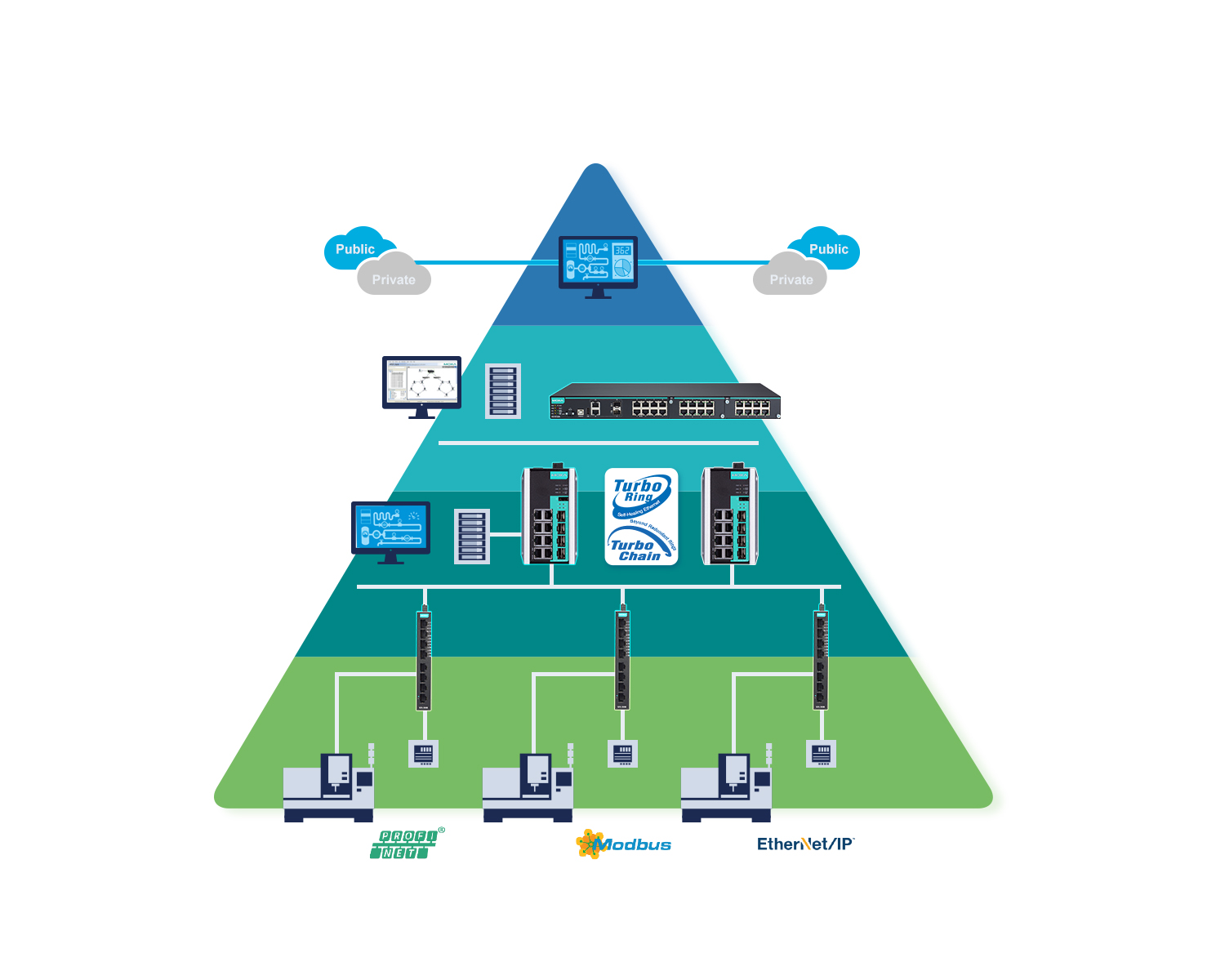

Using industrial-grade network devices for cross-platform systems

Solutions:

- An industrial-grade Ethernet switch design enhances network reliability

- Network redundancy with fast recovery within 20 ms for up to 250 nodes (*Note: 10G/1G Ethernet recovery time within 50 ms)

- Seamless SCADA/HMI integration that supports mainstream industrial protocols

Case Study

Integrated Automated Material Handling

Location: China

A leading wearable devices manufacturer has built an interconnected factory, which involves multiple connections between smart SMT production lines in both the physical and cyber worlds. In order to keep operations smoothly and ensure sufficient bandwidth for their Industry 4.0, flexible production applications, they adopted Moxa’s full-Gigabyte managed switches to connect production data in OT environments with MES, guaranteeing industrial-grade and reliable data transmissions.

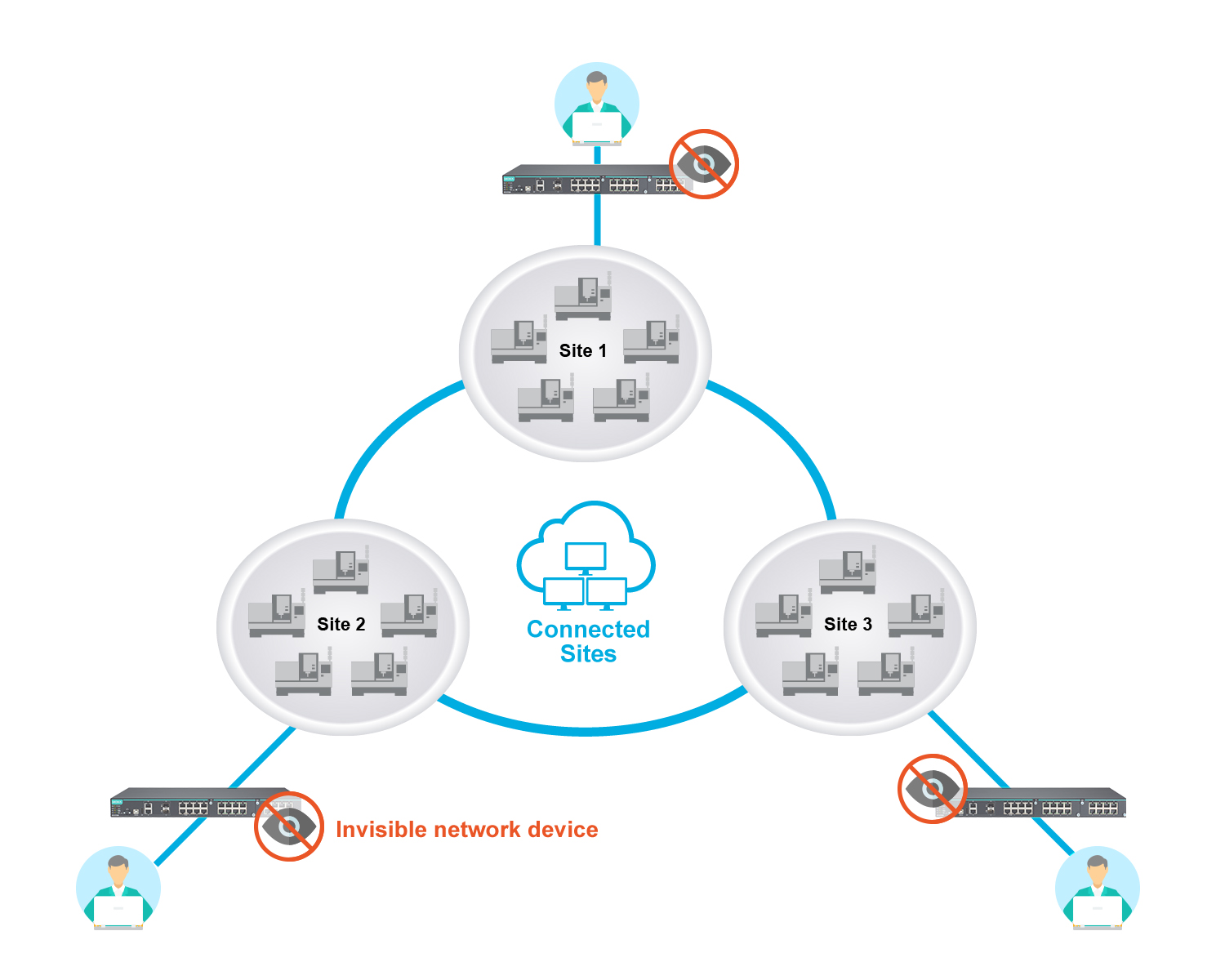

Invisible Large Networks Mean Unreliable Networks

Seeing the performance data of your production equipment can ensure operational reliability. At the same time, the visibility of network devices is just as important as production machines to maintain reliable and efficient factory operations. What if we can simplify your network management on a large scale?

IIoT Connectivity:

Connecting thousands of network devices in one network

Problems:

- The risk of network failure increases when thousands of network devices and machines are invisible

- Have to operate multiple systems and software separately to manage network devices and physical connections

Simplified:

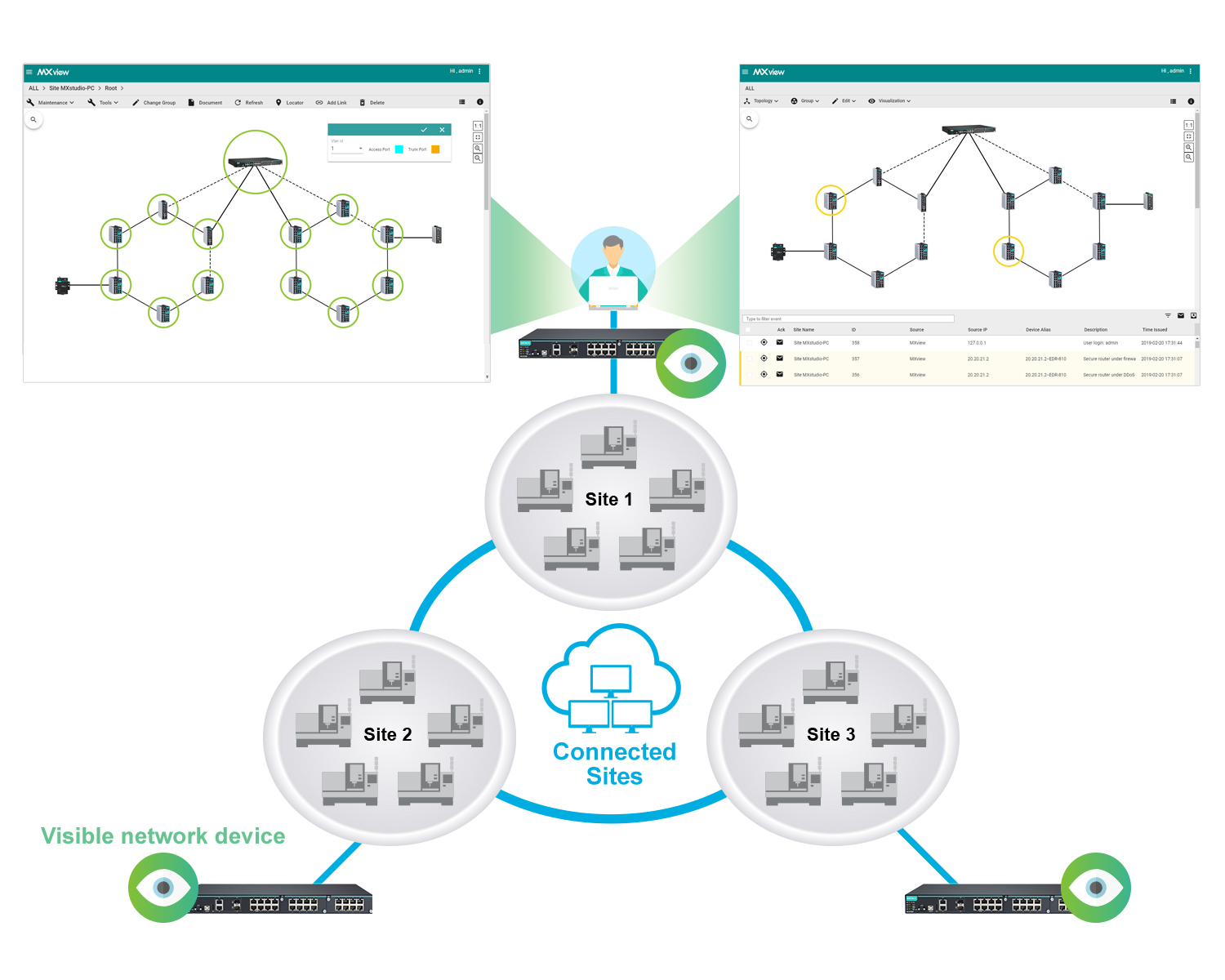

Visualizes network devices to ensure operational reliability

Solutions:

- Manages a large-scale network with an industry-grade network management solution via a web browser

- Generates OPC 2.0 compliant tags automatically to integrate with SCADA/HMI applications

Case Study

Managing a Large-scale Network in an Interconnected Factory

Location: China

A leading home appliance manufacturer has built an interconnected factory, which involves a multitude of connections between smart machines and production lines at multiple sites. To ensure seamless data transmission between production lines and back-end MES and ERP systems, reliable network connectivity was required, so they adopted our industrial network management software to monitor the industrial Ethernet switches to easily diagnose and pinpoint failures in a large-scale network.