Simplify Connectivity for Smart Manufacturing

Enabling IIoT connectivity to perform remote monitoring and predictive maintenance, and transform your business

Acquiring and preprocessing diverse data to perform predictive maintenance

In order to achieve optimized results for predictive maintenance, it is critical to leverage edge computing capabilities to preprocess data from a diverse set of data sources. This data is acquired through a variety of sensors added to key components. Managers can implement appropriate measures in good time, be prepared for any event, and autonomously perform maintenance before machine failure truly occurs. Find out how to address the challenges in performing diverse data acquisition and deploying edge intelligence for predictive maintenance.

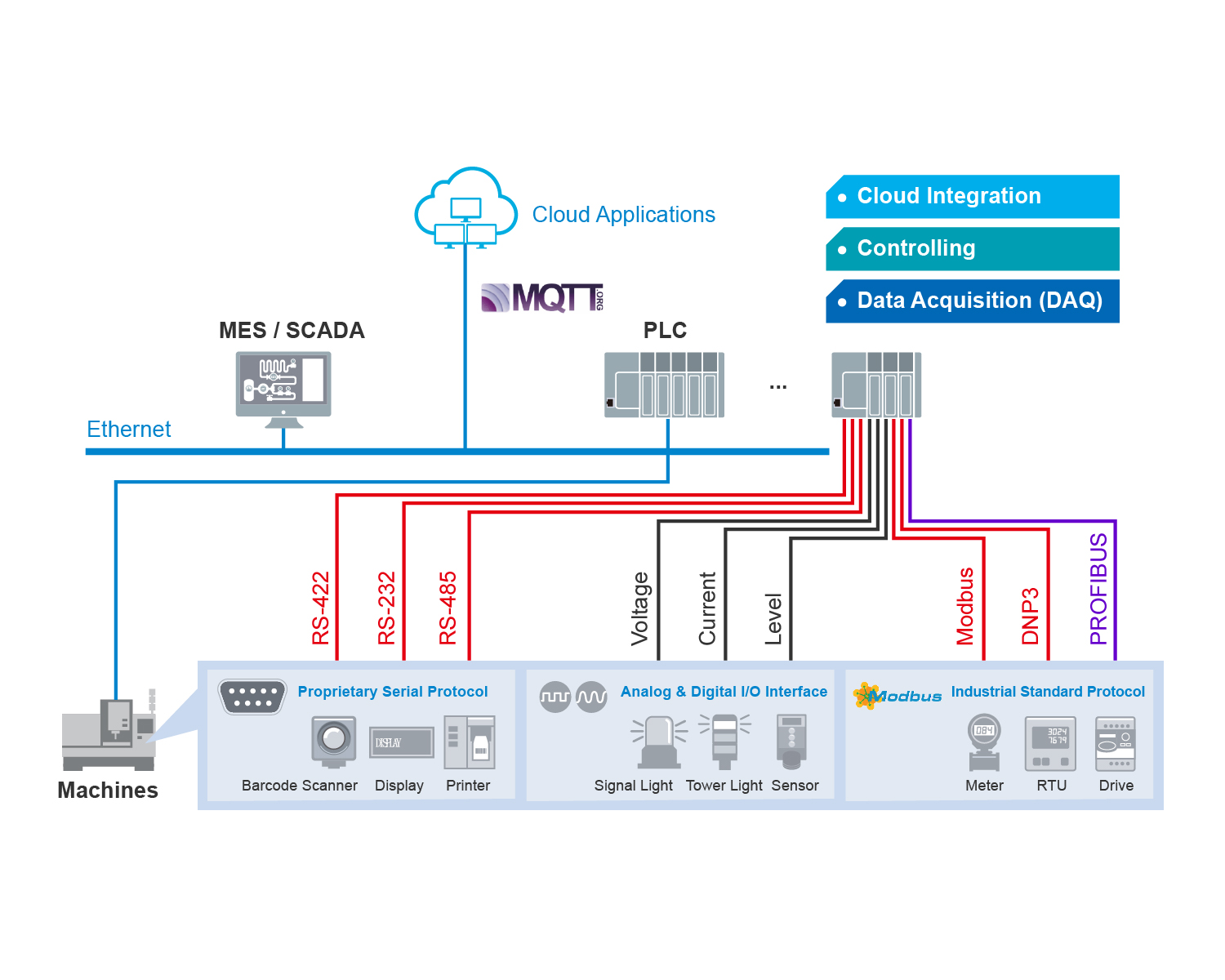

Diverse Data Acquisition Makes Connectivity Complex

Adding more sensors nearby key components to acquire big data can increase predictive accuracy. However, data acquisition gets complicated because of the large number of different protocols and interfaces used by the different sensors.

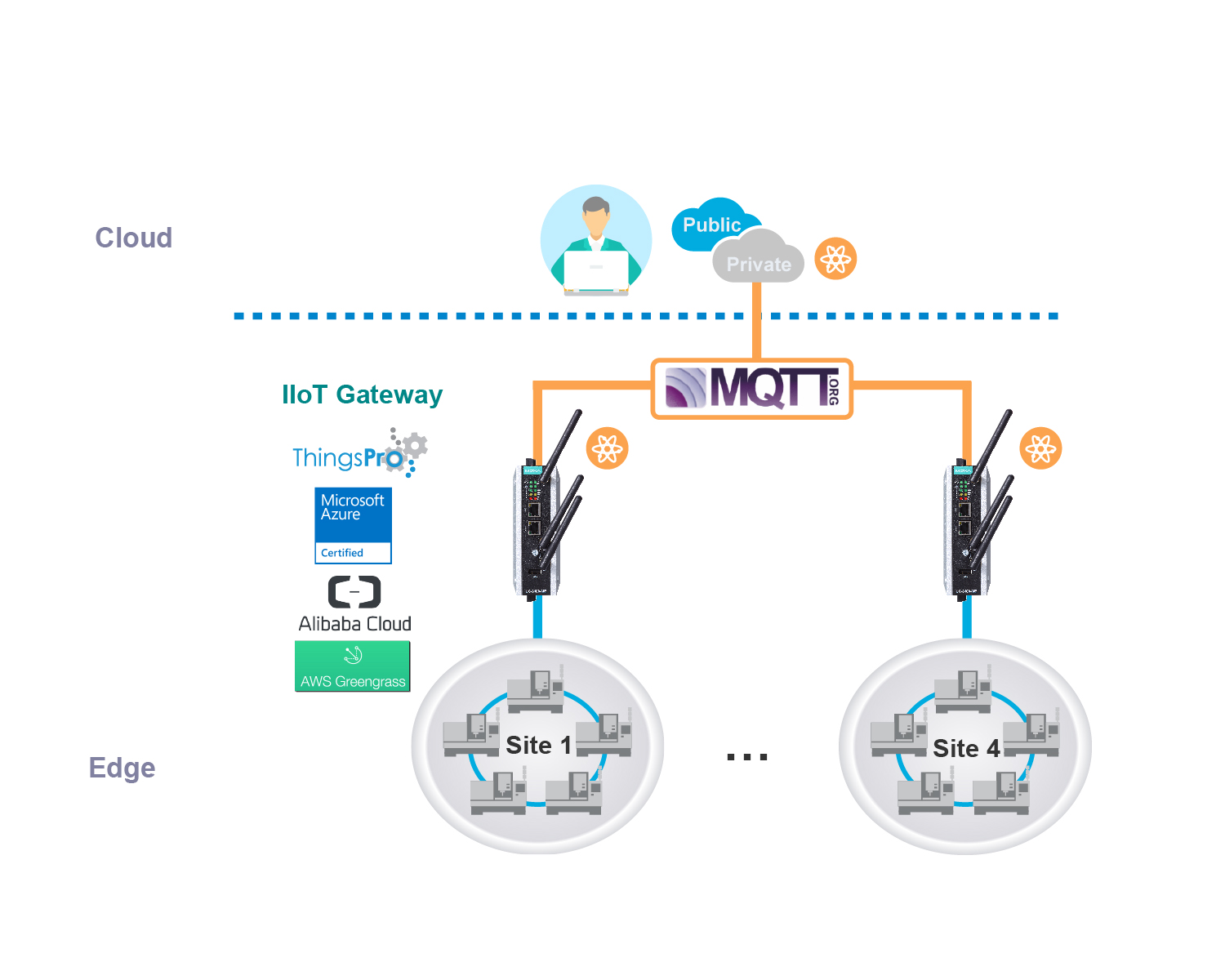

IIoT Connectivity:

Connecting different sensors with different interfaces and protocols

Problems:

- Arduous programming efforts to realize edge-to-cloud connectivity from scratch

- Additional communication PLC modules for protocol converters are required, making it more expensive

- Legacy PLCs may not have the capability to communicate in cloud protocols such as MQTT

Simplified:

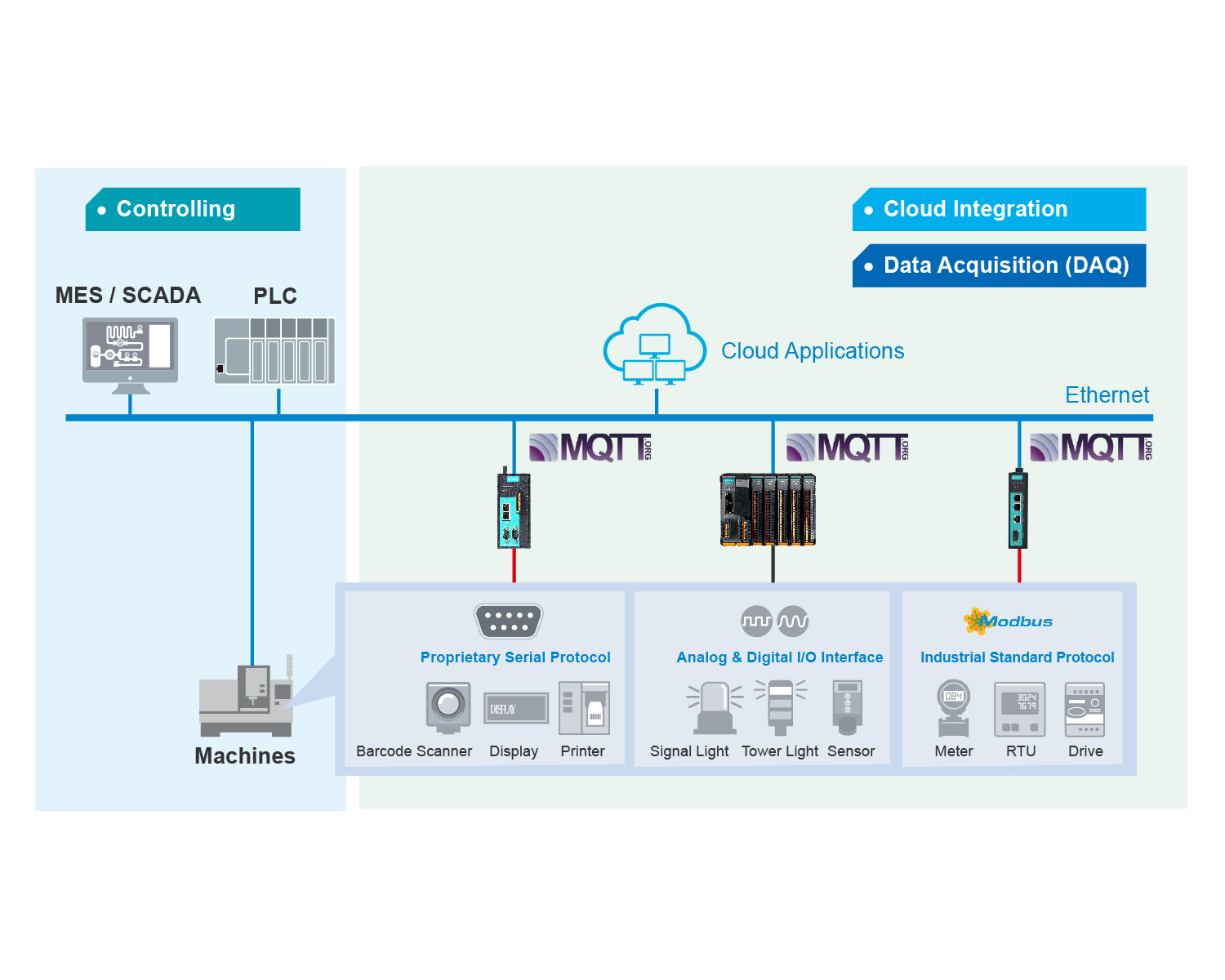

Separating controlling and connectivity

Solutions:

- Easy and quick deployment from edge-to-cloud that includes cloud selection, connections, message tags settings, and data mapping with intuitive UIs

- Supports connecting loss buffering to prevent data loss when communication has been disrupted

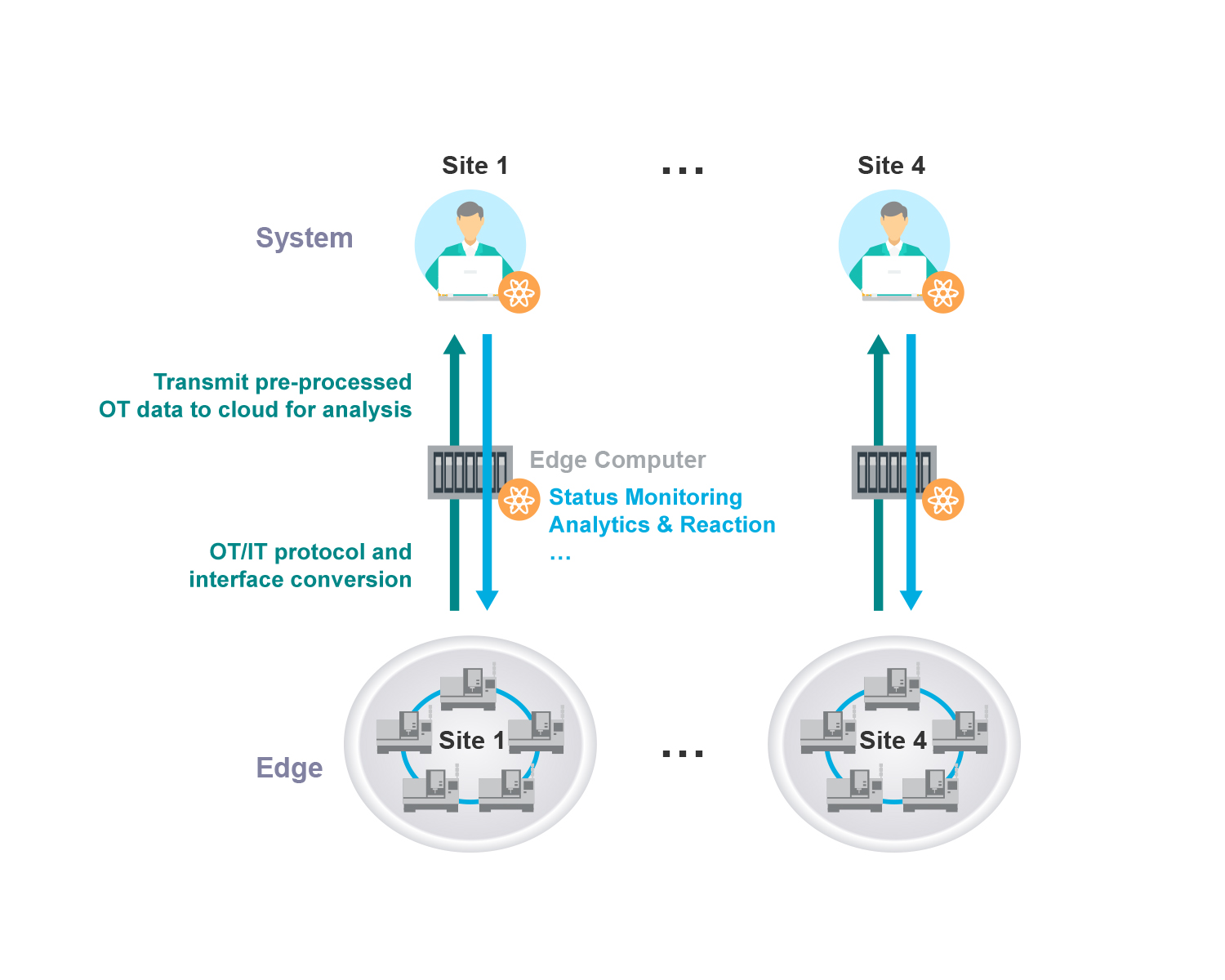

Deploying Edge Intelligence Is Hard to Start With

Sending all raw sensor data to the cloud is the best approach to do predictive analysis. However, deploying edge computing in multiple sites for data preprocessing saves you more on network bandwidth and allows you to anticipate and preempt machine failure. What if we can simplify your large-scale edge computing deployment?

IIoT Connectivity:

Deploying edge computing at each site

Problems:

- Edge computing in large-scale deployments requires more people and time to integrate, deploy, and redeploy devices

Simplified:

Easy distribution of cloud technology to the edge in large-scale applications

Solutions:

- Ready-to-run conversion software allows you to convert OT and IT protocols easily

- A configurable user interface

- Support for cloud technologies, such as Azure IoT Edge, AWS Green Grass or Aliyun Link, allows for the extension of cloud intelligence to edge devices

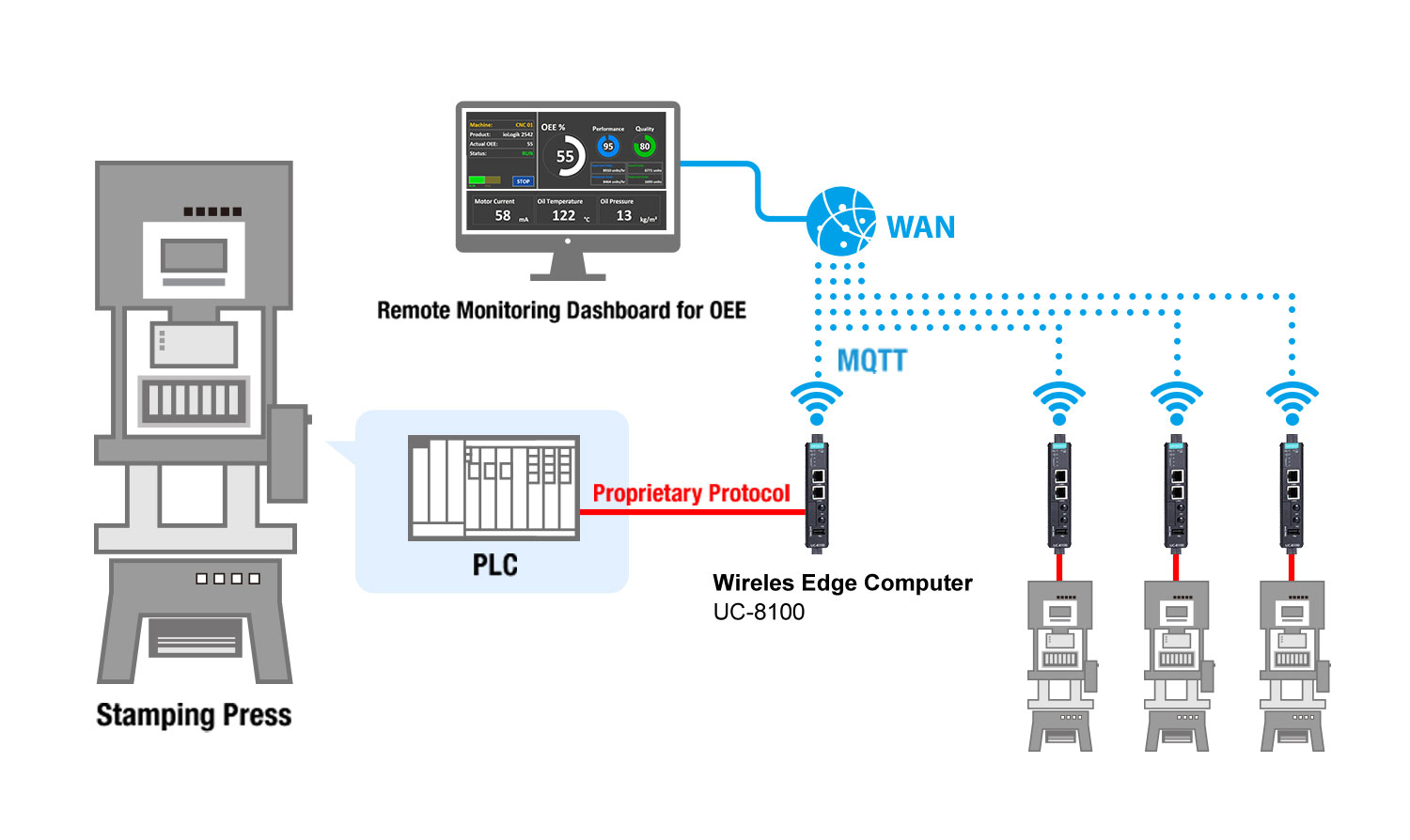

Case Study

Machine Data Acquisition through PLCs for Machine Tool Builders

Traditional machine tool builders are now willing to invest in new IIoT trends so that they can add more value to their products and improve the quality of their post-sales management and services. The UC-8100 Series embedded computer collects proprietary machine status data from different brands of PLCs (e.g., Mitsubishi, Delta, and Allen-Bradley), sends the data to the backstage control server, and displays the data on a dashboard remotely and locally.