EVO40 is the only separable switch-disconnector on the market: the safety benefit is unquestionable. With a conventional switch-disconnector, the switchover to OFF can’t be 100% guaranteed, in the event of an overvoltage with melting of the contacts; with EVO, a fully visible disconnection is ensured because of its separation in two, thus allowing a safe disconnection. In addition to this aspect, the product is safe for two other important reasons.

The first is that the user does not have access to the active parts (IP4X).

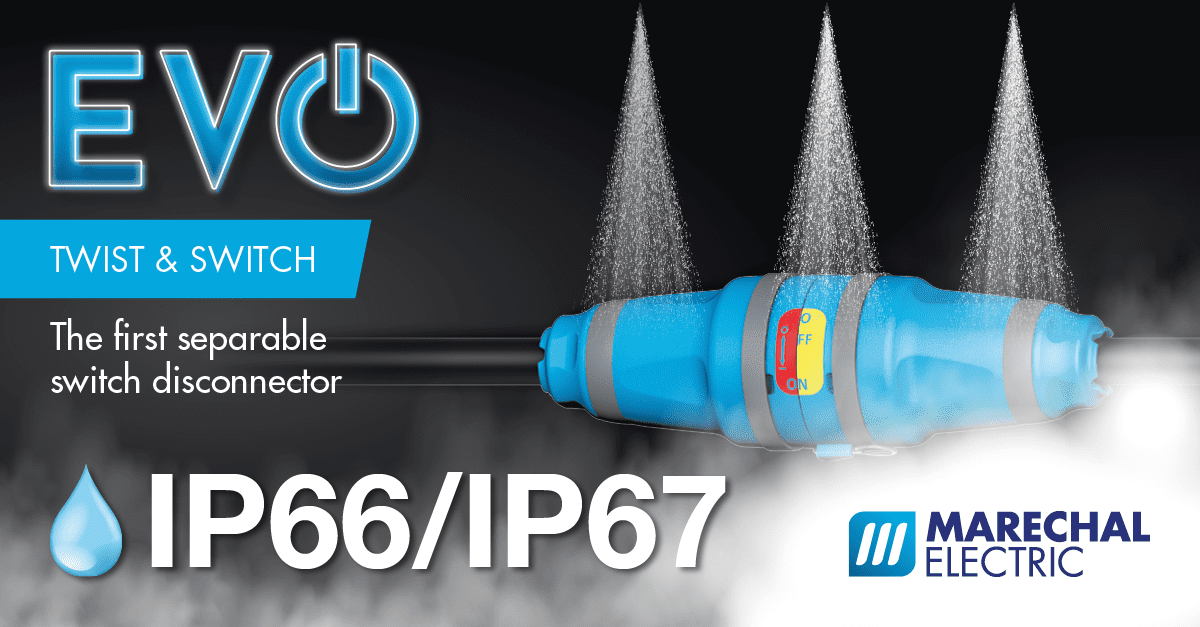

The second is that the product is IP66/IP67 waterproof in the ON & OFF positions but also when switching from one to the other. This ensures that even when the product is connected, it is watertight.Reminder of the IP indicator meaning.

| First digit | Second digit | ||

| 4 | Resistance to solid particles/tools 1mm | 4 | Resistance to water splashes |

| 5 | Resistance to dust | 5 | Resistance to water jets |

| 6 | Dust tight | 6 | Resistance to powerful water jets |

| 7 | Resistance to temporary immersion up to 1m | ||

| 8 | Resistance to prolonged immersion beyond 1m for a defined time | ||

| 9 | Resistance to high pressure water jets |

IP66/IP67 WATERPROOF, WHAT ARE THE ADVANTAGES FOR THE FOOD INDUSTRY?

EVO ensures continuous waterproofness even under powerful water jets. As a result, there is no need to cut off the power, cleaning can be done safely.

In addition, EVO’s ergonomics have been studied to ensure that there is no retention zone: food cannot get stuck in the product. The product durability is ensured and the hygiene of the installations respected.

As the switch-disconnector can be disconnected easily and locally, by a simple “twist” movement, machine changes are easier and faster. For plants that manufacture various products, this makes it possible to switch from one production line to another in a minimum amount of time.