Network Management Software (NMS) is a common tool for IT engineers to monitor, manage, and optimize IT systems, such as Ethernet switches, routers, computers, and servers. However, most operation technology (OT) engineers only utilise SCADA for monitoring OT systems and machines, as most machines are connected by Fieldbus and legacy serial interface, thus, the concept of “Network Management” is rarely considered in the field of OT.

Edge Connectivity is the Blind Spot of OT Networks

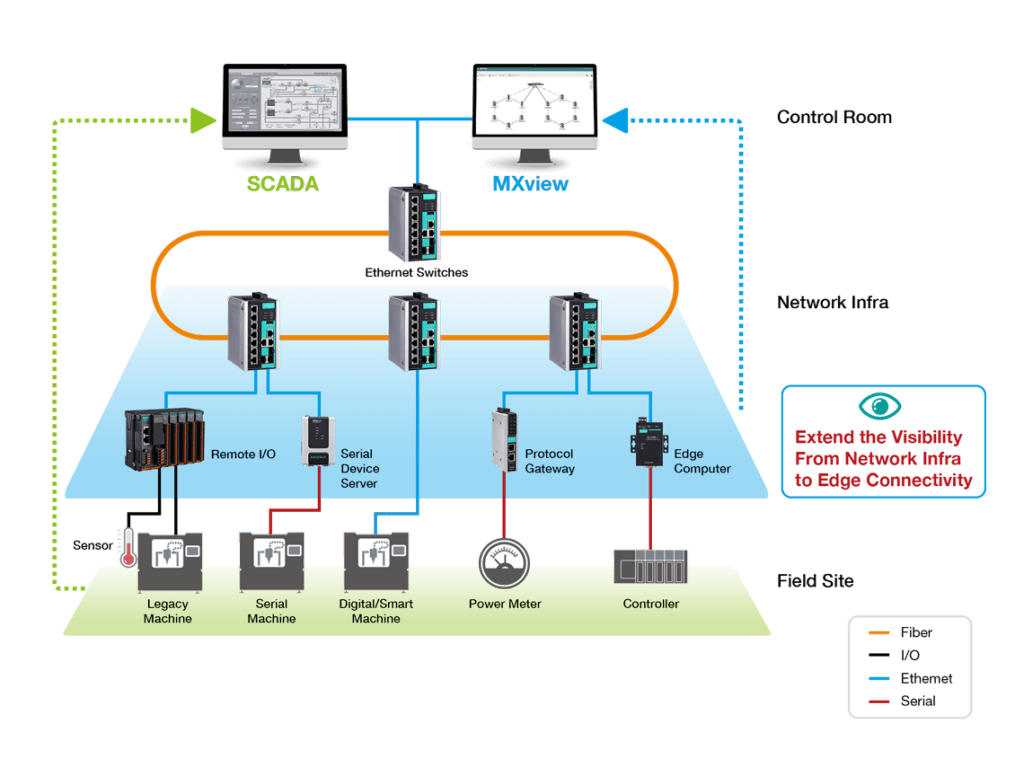

“Ethernet” has become mainstream and has been widely used in industrial automation networks. However, many onsite machines and devices with serial, I/O, and other hardwired interfaces are not updated simultaneously due to high cost, which requires edge connectivity hardware, such as serial device servers, protocol gateways, I/Os, or edge computers, to communicate with Ethernet infra.

As IIoT technologies and Industry 4.0 have progressed, networks have become larger and more complicated. Thus, OT network management becomes crucial and drives factory operators to implement OT NMS for efficient monitoring. However, like IT NMS, many types of OT NMS only monitor network devices such as Ethernet switches and routers. Thus, edge connectivity in the field sites is currently the blind spot of OT networks.

Extend Network Visibility to Edge Connectivity with Moxa MXview

With over 30 years of industrial automation experience, Moxa, a leading industrial networks and connectivity solution provider, provides comprehensive OT NMS solutions. MXview supports OT engineers by extending network visibility from network infra to edge connectivity. The features detailed below enable efficient event monitoring and network management:

Visibility:

Fast troubleshooting

Easy integration with SCADA by supporting OPC DA tags or RESTful APIs, MXview can assist operation visibility cover machines, network infra, and edge connectivity. Once SCADA shows alerts, OT engineers can quickly verify whether errors relate to the machine, network devices, or edge connectivity, and implement fast troubleshooting to shorten system downtime.

Prevention:

Avoid unexpected issues

Security:

The proper setting

Insights: Better management and investment

Application: MXview Supports Numerous Protocol Gateways Performance Monitoring in FMCS Applications

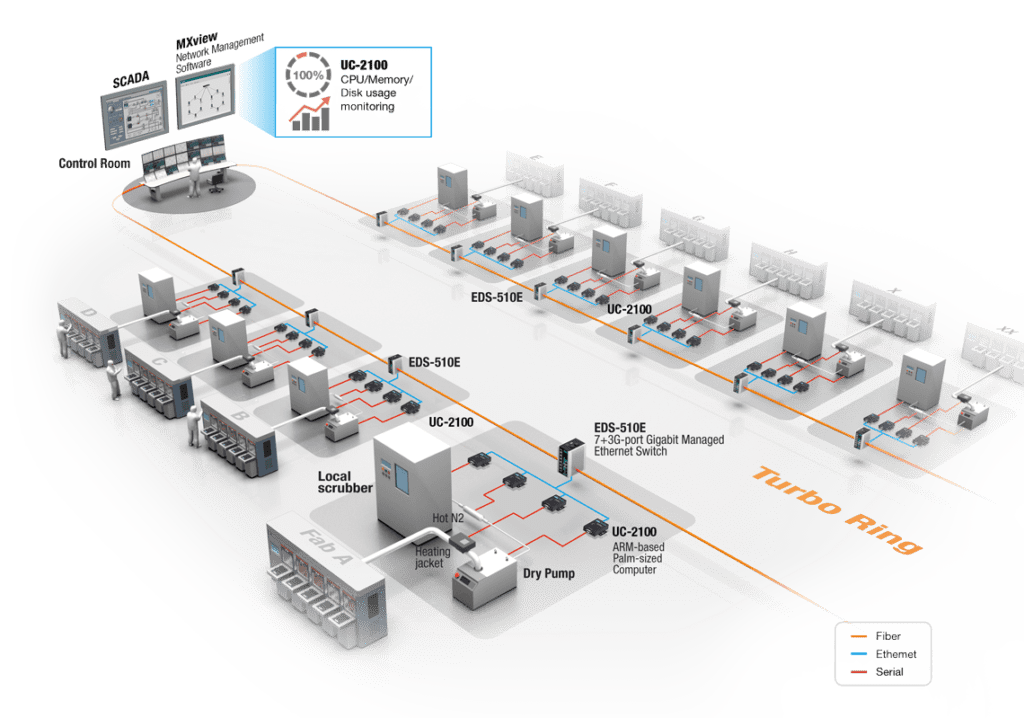

With the IIoT trend, semiconductors and chemical factories have begun to implement big data acquisition and analysis into FMCS applications to improve environmental monitoring and production efficiency. Moxa has enabled a one system integrator to build a reliable network infra and edge connectivity with EDS Series Layer 2 Ethernet switches and UC Series computers as protocol gateways, to collect and convert data from multiple protocols of dry pumps and machines in field sites for real-time machine monitoring.

Moreover, Moxa MXview provides the user with a monitor interface, with visibility covering network infra and a large amount of edge protocol gateways performance for efficient network management.

System Requirements

- Stable performance of protocol conversion among different devices and machines in limited space

- Lower efforts on monitoring numerous network devices and protocol gateways. For example, CPU usage monitoring can prevent downtime risks, such as DDOS-attack, software bugs, or wrong process which cause the overloading of protocol gateways

- Secure and reliable and redundant network performance in harsh environments, for example, in the event of electrical interference

Why Moxa

- An industrial compact size ARM-based computer with rugged fan-less design provides multiple protocol conversion (Serial/Ethernet/USB/I/O) for data acquisition

- Moxa Turbo Ring provides redundancy topology for millisecond network recovery

- Moxa MXview provides complete visibility on network infra and edge connectivity topology, security levels and settings, and also monitors functions of key network components for predictive maintenance, such as fiber check, CPU/memory/disk usage, etc.

MXview Supported Edge Connectivity Product Portfolio

Moxa Network Management Software

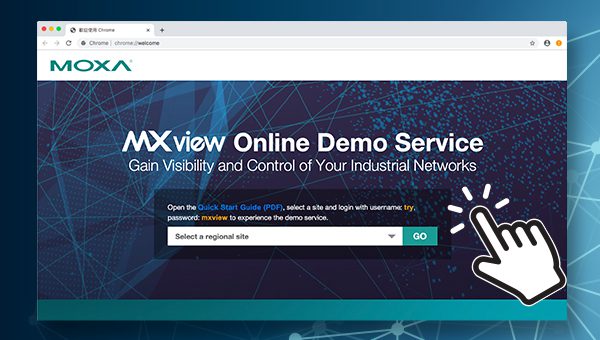

Get Free MXview Trial

Experience Moxa MXview. Get Free Access to the MXview Demo Site Now

Email us